How to judge the quality of thin film capacitor:

1) First of all, look at the appearance. If there is a problem with the appearance, the film capacitor is likely to have a problem.

2) If there is a capacitance meter, measure whether the capacitance value is consistent with the mark on the shell.

3) Room temperature test performance, including capacity, loss, insulation resistance, withstand voltage, ESR, etc. In particular, the performance of the capacitor needs to be tested.

4) The simulated life test was carried out. Normal temperature test performance is no problem, but also to see whether the life can last.

5) Choose a reputable capacitor manufacturer.

6) If the use requirements are not high, you can buy some general-purpose from the market, do a copy of the machine test, passed, you can rest assured to use.

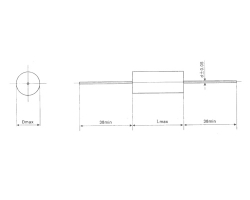

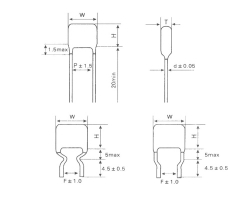

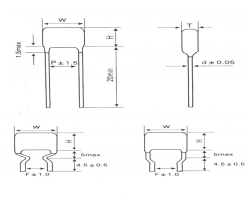

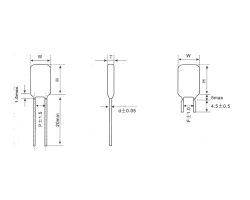

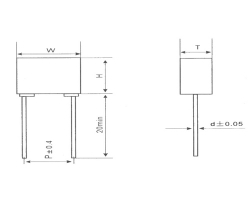

7) Thin film capacitor is a kind of capacitor with metal foil as electrode, which is overlapped with polyethylene, polypropylene, polystyrene, polycarbonate and other plastic films from both ends to form a cylindrical structure. According to the type of plastic film, they are also called poly ethyl ester capacitor, polypropylene capacitor, polystyrene capacitor and polycarbonate capacitor. Thin film capacitor has been used in recent years to gradually improve the use of a capacitor, so we need to understand the inspection and treatment of thin film capacitor.

The working principle of thin-film capacitor is the same as that of ordinary capacitor. It stores electric energy by storing charge on the electrode. It is usually used together with inductor to form LC oscillation circuit. The working principle of capacitor is that the charge will move under force in the electric field. When there is a medium between conductors, it will hinder the charge movement and make the charge accumulate on the conductor, resulting in the accumulation and storage of charge.