Paper dielectric capacitor is a kind of capacitor which is composed of paper with very thin dielectric thickness as medium and aluminum foil as electrode, which is wrapped into a cylinder after being covered, and then encapsulated with an impregnated shell or filled with epoxy resin. It has the advantages of low cost, but large loss. It is mainly used for bypass, coupling and filtering in low frequency circuits.

Paper dielectric capacitor is a kind of capacitor with paper as its medium. In fact, it is not only capacitor paper that acts as capacitor medium, but also composite medium impregnated by capacitor paper through impregnation material. This composite medium and electrode plate are used to form capacitor.

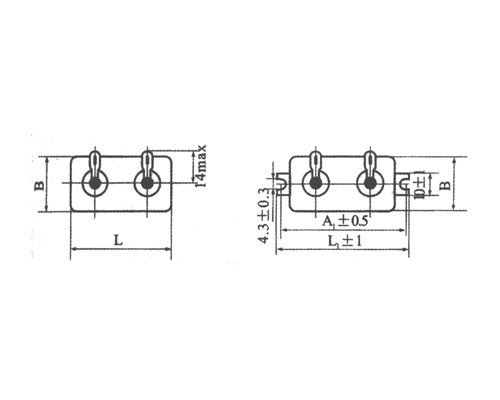

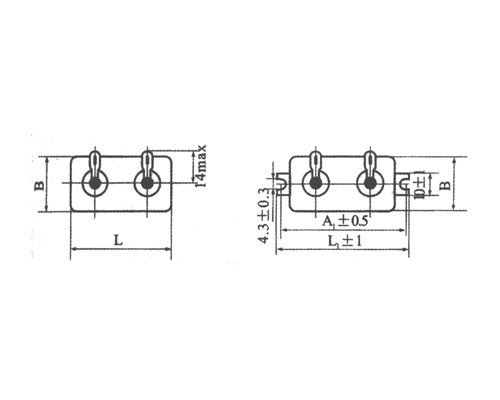

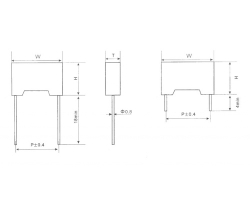

The capacitor paper and the electrode plate are wound into a core, then impregnated (the impregnating material is polar or non-polar, there are solid, liquid and semi-liquid), and then sealed. The sealing forms include aluminum shell filled with resin, iron shell, high pressure and even ceramic shell.

Paper capacitors are only used in DC and low frequency circuits. The dielectric strength of the capacitor decreases with time. The thermal stability of the capacitor is poor, so the stability of capacitance is not high, the working temperature is low, and it is easy to absorb moisture. Therefore, good sealing conditions are required to ensure the quality of the capacitor.

There are two winding methods for paper capacitor: inductive and non inductive. The inductive core is actually a strip coil with many turns, so the inductance is large. The non inductive type is to stagger the electrode foil to both sides of the paper, so that the side of the foil strip extends out of the paper tape, and then the lead wire is welded after winding into a cylindrical core. In this way, the coils of electrode foil are short circuited with each other, so the inductance is very small. This kind of capacitor can be used at higher frequency.